General information

Smoke removal, smoke and heat extraction systems

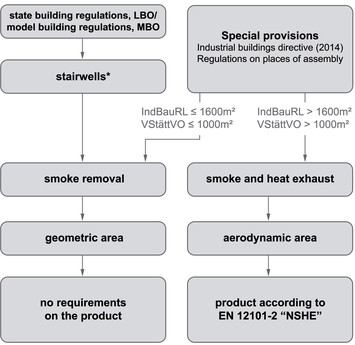

Building regulations make a distinction between

smoke removal systems and smoke and heat extraction systems.Smoke removal systems are openings that possess geometric smoke outlet areas (Ag). Building regulations do not pose any specific requirements on the manufacturing of a smoke removal product.

The general formula used to calculate the necessary area reads: Ag = a · b

The calculation may include all openings as long as it takes into consideration all obstacles, such as window reveals and window lintels, and factors in that area Ag must not be greater than the clear area of the window.

Smoke and heat extraction systems are devices with smoke outlet areas (Ag) that possess an aerodynamic effect. The requirements posed on these natural smoke and heat extraction systems (NSHE) are spelled out in standard EN 12101-2. Among other things, these requirements call for wind tunnel measurements to determine the aerodynamic coefficient (Cv0), temperature and snow load tests as well as long-term tests to evaluate the system’s suitability for NSHE and ventilation purposes. An NSHE system is always composed of a unit that comprises a window with drive(s) and all necessary fitting parts.

The formula used to calculate the necessary area reads:

Aa = a · b · Cv0

The value Cv0 is given in the relevant test results and varies with the installation position and the opening angle of the window.

These is no general stipulation as to which conditions demand the use of smoke removal systems as opposed to a certified NSHE system. For the requirements that apply in your specific situation, refer to the relevant state building regulations (LBO) and the model building regulations (MBO) as well as to the applicable guidelines and regulations such as the Model Industrial Buildings Directive (MindBauRL) or the Regulations on Places of Assembly (VStättVO).